产品详情

Servo soldering machine alias pulse hot press, welding machine, haba soldering machine, pressure welding machine

Main application industries:

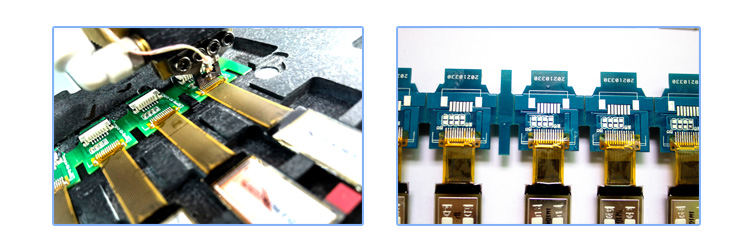

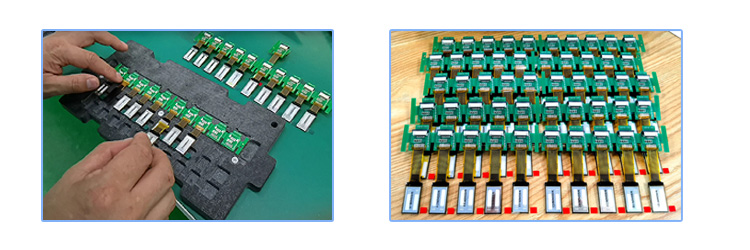

1. Hot pressing and welding of flexible circuit board in LCD, PDP, mobile phone and other electronic products.

2, HDD, coil, capacitor, motor, sensor and other enameled wire soldering.

3, computers and other communication machines in the cable, connection port (USB/HDMI) welding.

4. Welding of CMOS, CCD and FPC boards for digital cameras and mobile phones.

5, Bluetooth headphone PCB board and FPC line welding.

6, the gold wire inside the microwave device hot pressing combination.

7, ink-jet printer motherboard, thermal printing head ceramic device connection FPC welding

8, medical instrument PCB board and FPC line welding

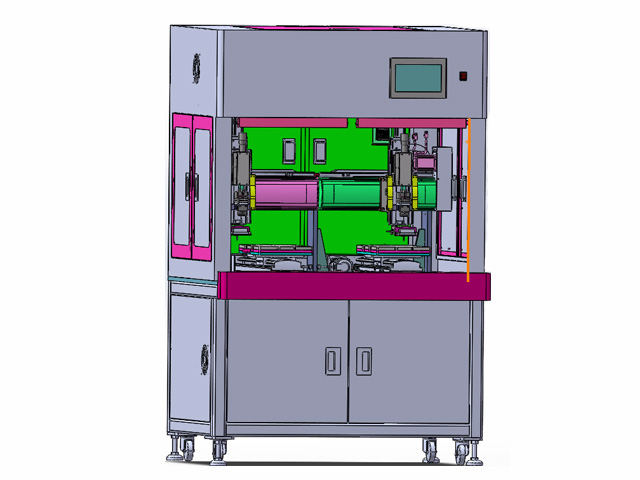

Characteristics of the equipment:

Temperature control system: Japanese RKC temperature control system, accurate control of solder temperature within ±1℃

Pressure control: customized pressure tracking mechanism is adopted to accurately control the solder pressure, and the pressure adjustment control range is ±1N

Height adjustment: 1, according to the thickness of the product and different fixture, using a key positioning system, automatic focus on the product and the actual height of the head

2, servo motor control to adjust the head height, can directly input fine-tuning data, precise control fine-tuning range ±0.02mm

3, product batch welding, servo motor control to adjust the speed and distance of the material moving platform, can directly input fine-tuning data

Control system: according to different solder requirements of products, can save multiple sets of solder parameters, easy and quick product switching, can call system parameters at any time.

Double welding platform independent control, suitable for plate, whole plate and other products, the servo can be moved forward and backward, left and right, in many ways, to meet the welding requirements of multiple products and multiple solder joints

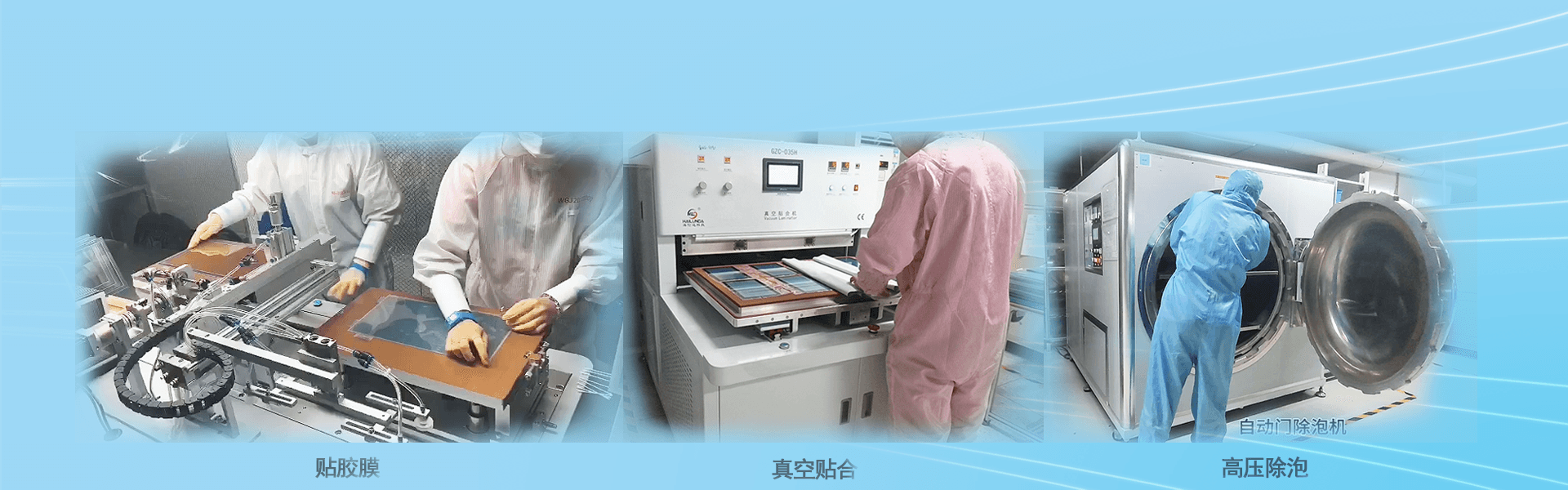

Pulse welding principle:

1. The heating method of pulse power supply is to use the joule heat generated when pulse current flows through high resistance materials such as molybdenum and titanium to heat welding. It's usually heated

The front end of the nozzle is connected with a hot spot couple, and the power generated thereby feeds back to the control power supply in real time to ensure the correctness of the set temperature.

2, pulse current heating device is instantaneous heating mode, only in the need to melt solder energized heating.

3, metal solder tip with current through the heat after melting solder. After the solder melts, stop electrification and cooling. Pressurized until the solder solidifies,

High - reliability welding without virtual welding, floating welding can be obtained.